Many products we’ve manufactured can’t be displayed but include the following system types aerospace landing gear and braking, flight control surface actuation, precision motion control with polygon interfaces, optics and position/guidance control just to name a few. We thrive on providing manufacturing solution to your complex and challenging CNC Machining needs. Check out some of our CNC machining projects below to get a more in-depth insight into our capabilities! Dimensions listed are for the largest part in the photo.

.25” x 2” x 2”

6” ∅ x 4”

2” x 3.5” x 3.5”

1” x 1” x 1.5”

.875” ∅ x 2”

.875” ∅ x 1.75”

9.5” ∅ x 4”

7” x 3.5” x 2.25”

2.75” x 2.25” x 1”

7” x 2.5” x 1.5”

3.25” x 2” x 1.25”

4.75” ∅ x 7.5”

2.25” x 1.35” x .5”

1.5” ∅ x .6”

3” ∅ x 9”

3.2” ∅ x 2.4”

9” ∅ x .2”

8.75” x 2” x 1”

3” x .68”

2.875” ∅ x 2.5”

8” x .5” x .25”

11.5” x 4” x .5”

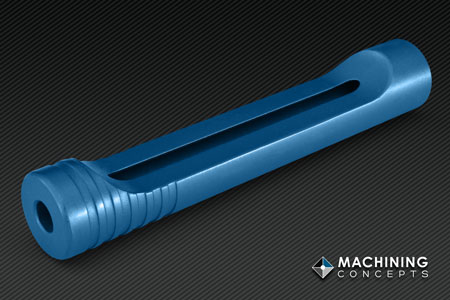

5” x 1.5”

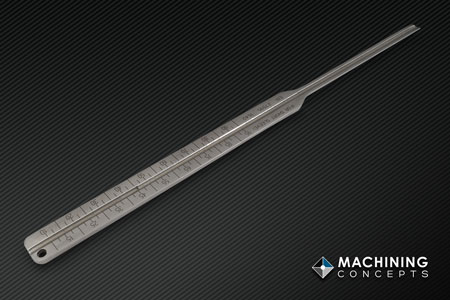

6” x .25”

2” ∅ x .875”

7” x 2” x .7”

11.5” x 4” x .5”

4.65” x 1.75”

2.6” x 1.4” x .4”

.75” ∅ x 2.8”

8.75” x 8.75” x .625”

9” x 8” x 4.5”

1.95” ∅ x 4.25”

.75” ∅ x 4.25”

6.25” ∅ x 1”

3” x 2.5” x .6”

2” x 1.8” x 1.8”

4.5” x .5” x .4”

4.5” x .8” x .8”

15.5” x 6” x 1.25”

4” x 1.75”

About Machining Concepts

Machining Concepts (MC) produces high precision medium to small machined parts and mechanical assemblies as a contract manufacturer to the aerospace, automotive, electrical component, medical device, military, off-road vehicle, and general industrial markets. Our state-of-the-art manufacturing facility uses the latest CNC machining technologies to produce complex and intricate machined components that meet or exceed the most demanding tight tolerances. Products machined from bar stock, castings, forgings, tubing, and billets weigh up to 30 pounds. MC operates in a climate-controlled AS9100D / ISO 9001:2015 certified machine shop in Germantown, WI, and has been providing machining services since 1995.