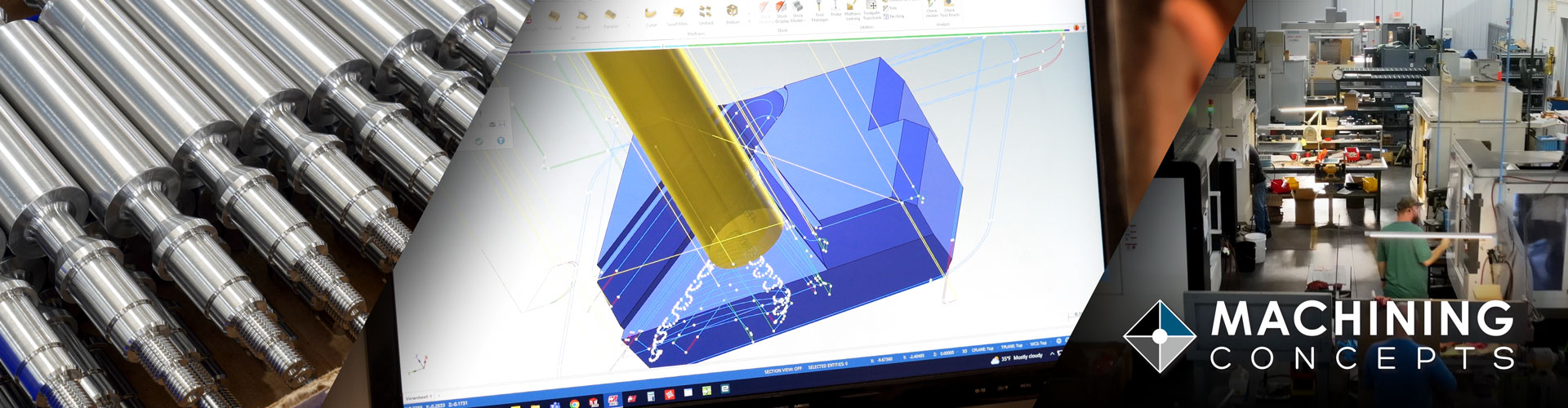

Machining Concepts (MC) produces high-precision CNC machined parts and mechanical assemblies as a contract manufacturer to the aerospace, automotive, defense, electrical component, medical device, military, off-road vehicle, and general industrial markets. Our state-of-the-art manufacturing facility uses the latest CNC machining technologies to produce complex and intricate machined components that meet or exceed the most demanding tight tolerances. Products machined from bar stock, castings, forgings, tubing, and billets - weighing up to 30 pounds. With +25 years of experience, we are experts at converting High Temp Alloys (718 Inconel, Hastelloy, Rene 41, Waspaoly, Monel etc.) stainless steels (Incl Nitronic 60), copper, brass, aluminum, titanium, gray-iron castings, and medical-grade plastics into precision parts.

Small-part machining requires extreme skill, the proper CNC machines, precise cutting tools, and a complete understanding of a machine’s capability to produce precision milled and turned parts. In addition to turning and milling, MC utilizes Swiss lathes. In a Swiss lathe, the material being cut is supported by a precision guide bushing and is positioned using a sliding headstock (Z-axis). The result is a cutting condition of a fully supported workpiece through the entire length of the Z-axis stroke. Great for making high L/D ratio parts and for generally small workpieces.

MC is pleased to join the Trace-A-Matic manufacturing group. Trace-A-Matic, a world-class machine shop, is a CNC industry leader in machining large parts. Machining Concepts expands the group’s overall capability with our highly skilled team and high-speed machine tools for small-part machining, benefiting all our customers.

Many products we’ve manufactured can’t be displayed but include the following system types aerospace landing gear and braking, flight control surface actuation, precision motion control with polygon interfaces, optics and position/guidance control just to name a few. We thrive on providing manufacturing solution to your complex and challenging CNC machining needs. We will “machine complete to print” using your materials and manage your entire supply chain as a Tier 1 supplier.

Please view our complete equipment list to get a closer insight into our technical capabilities.

Quality Management SystemMachining Concepts manufactures high-precision machined components managed by a rigorous quality control system with AS9100D and ISO 9001:2015 certification. Our dedication is to provide the highest quality, precision machining of mission-critical parts to exacting standards for the industrial sector; industries, including aerospace, automotive, electrical component, medical device, military, and defense. Our manufacturing process takes place in a state-of-the-art climate-controlled facility. |

|